Automatic Axial flux motor stator winding machine

Model number:ND-ZRX01

Introduction:The axial flux motor stator coil making machine adopts a single-station, manual loading, and automatic clamping mold to reduce the intensity of manual labor.

- Specification

Automatic Axial flux motor stator winding machine - Motor manufacturing solution

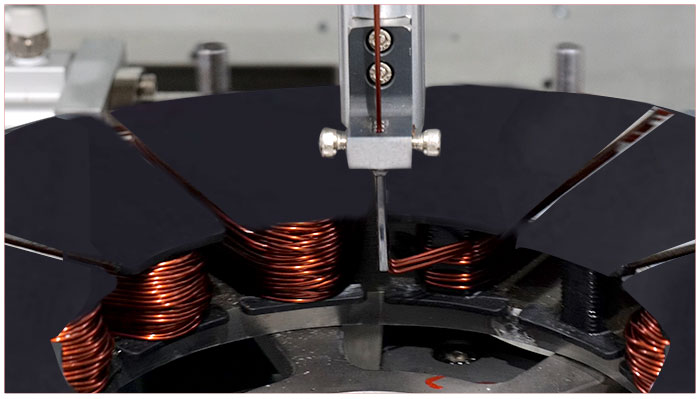

The needle winding machine is mainly used axial flux stator winding. With single station, manual loading, automatic clamping mold, reduce manual labor intensity; The winding process can realize multiple tapping (screen setting), clamping and cutting functions.

The number of slots and the number of turns can be set through HMI.

Technical Parameters of Axial flux motor stator coil winding machine

Product : Automatic Axial flux motor stator needle winding machine Servo mechanism: 2 sets of servo motor (X/Y axis) for winding; 1 set of servo motor (Z-axis) for wire distribution; 1 set of servo motor (S axis) for indexing. Power supply three phase 380V Stack height: 10-50mm Winding speed: 0---500 RPM (depends on wire size) Air pressure: 0.4---0.7 MPa Wire diameter: φ0.50—φ1.5mm Stator O.D: φ150—φ450 mm Total power: ≤8.5KW Application

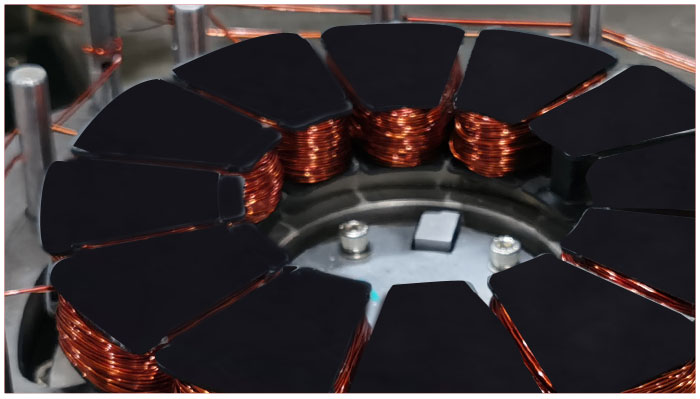

Axial flux motors have the technical characteristics of compact structure, flat and ultra-thin, small size, light weight and high power density. Suitable for new application scenarios such as electric motorcycles, airport pods, delivery trucks, electric vehicles, and even electric aircraft.

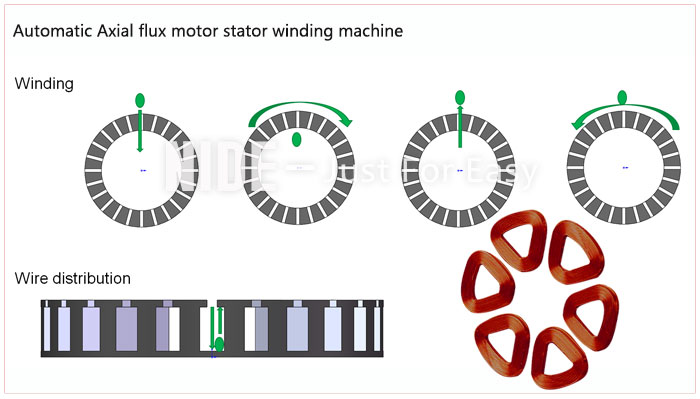

Axial flux motor stator winding machine process

1. Manual load, auto clamp stator;

2. Press Start button, machine auto winding, cutting wire;

3. Manual unload wound stator;

4. S, X & Z movement synchronously, achieve precision wire distribution;

5. Winding tension is controlled by electronic tensioner, including wire break detect function;

6. Winding needle Up/Down movement is controlled by Z axis servo motor, to achieve wire distribution at Z axis direction;

7. S & X movement synchronously, achieve winding process;

Axial flux motor stator winding machine show

Axial flux motor stator winding machine video

About NIDE

Nide is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.We can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.We also provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machine's application

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English