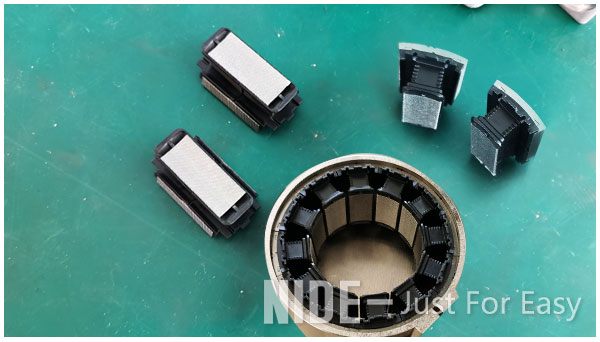

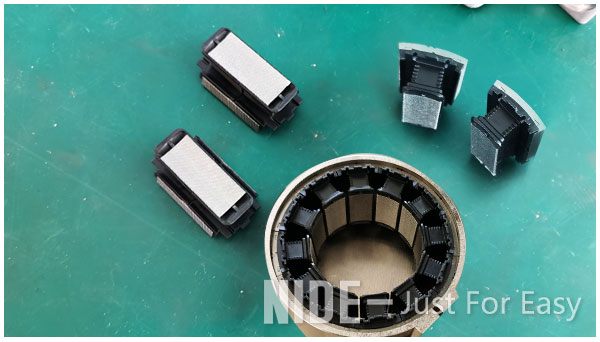

Segmented Stator Core Hot-Melting Machine

for BLDC Motor Manufacturing

The Segmented Stator Core Hot-Melting Machine is essential equipment for the thermal bonding

of segmented stator cores into a complete circular structure. It is widely used in the production of

BLDC (Brushless DC) motors, particularly for air conditioner motors, washing machine motors, and

automotive electric motors.

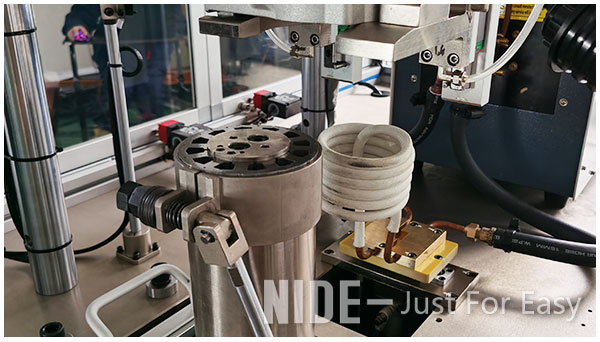

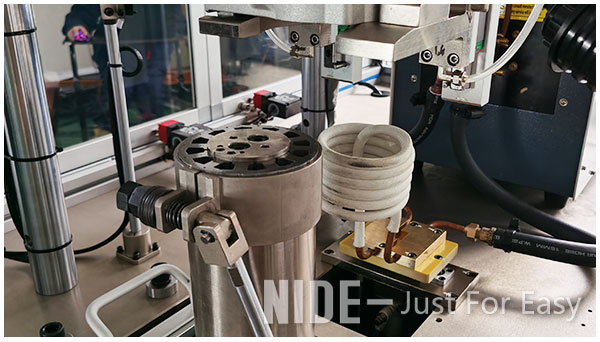

This machine adopts electric heating technology, transferring heat from the heating ring to the welding

surface of the segmented stator core. The segments are precisely fused and solidified into a rigid, concentric

stator ring with stable geometry and high mechanical strength.

Controlled via a PLC system and operated through a color touchscreen HMI, the machine is user-friendly,

reliable, and adaptable to various stator segment configurations.

Key Features and Advantages

Low Power Consumption & Efficient Heating

Utilizes electric heating with precise temperature control, ensuring uniform heat distribution and

energy efficiency.

Adjustable Pressing Head Structure

The press head is horizontally adjustable, making setup and debugging simple and fast for different

core designs.

Constant Temperature Control

Equipped with a digital thermostat, allowing operators to set and monitor heating temperatures

accurately.

Programmable Time Control

A digital display time controller enables precise adjustment of crimping duration, with wide timing

flexibility to meet different welding requirements.

Wide Application Compatibility

Suitable for hot-melt welding of segmented stator cores across multiple BLDC motor types, including

appliance and automotive motors.

Compact, Space-Saving Design

The machine features a compact footprint, clean design, and optimized layout, making it ideal for

modern stator assembly lines with limited space and high production demands.

Applications

BLDC Motor Stator Assembly

HVAC Motors (Air Conditioners)

Washing Machine Motor Production

Automotive Electric Motor Manufacturing

Small Appliance Motor Manufacturing

Technical Specifications (suggested addition for SEO completeness)

If available, consider adding a table for:

Heating Temperature Range: e.g. 100–300°C

Stator Segment Outer Diameter Range: e.g. 60mm–200mm

Power Supply: e.g. 220V/380V, 50/60Hz

Cycle Time per Core: e.g. ≤30s

PLC Brand (if notable)

Touchscreen Size: e.g. 7” color HMI

About NIDE - Your Reliable Partner in Motor Manufacturing Equipment

NIDE Group specializes in the R&D and manufacturing of motor production machinery. We offer a full range

of solutions including standalone machines, fully automatic production lines for armature and stator, and

complete motor assembly lines. With over a decade of experience, we support clients with high-efficiency

equipment and tailored automation solutions for various motor types.

Our product portfolio also includes motor components such as commutators, ball bearings, carbon brushes,

insulation paper, shafts, magnets, cooling fans, and motor covers. In addition, NIDE provides technical consulting,

project design, and turnkey services to help clients optimize their motor manufacturing processes.

Machines Application

NIDE machines are widely used in the production of various motor types, including:

AC motors / DC motors / BLDC motors / universal motors / induction motors

Single-phase and three-phase motors

Common application fields:

Household appliances: washing machines, air conditioners, vacuum cleaners, electric mixers,

electric shavers, hair dryers, electric toothbrushes

Industrial equipment: pumps, compressors, power tools, fans, coolers

Automotive: electric vehicles, hub motors, alternators

NIDE helps manufacturers build efficient, automated motor production lines for both high-volume

and customized projects. More information please check our New Website: www.nidegroup.com.

Global Service & Support

NIDE offers global installation support, training, and after-sales services. Our engineering team ensures

smooth machine integration and continuous production performance. Contact us for technical consultation

for guidance on equipment selection.

Contact Us

marketing8@nide-group.com (Head of Electric Machinery and Equipment)

emarketing@nide-group.com (Head of Motor Parts)

SNS

中文版

中文版 English

English