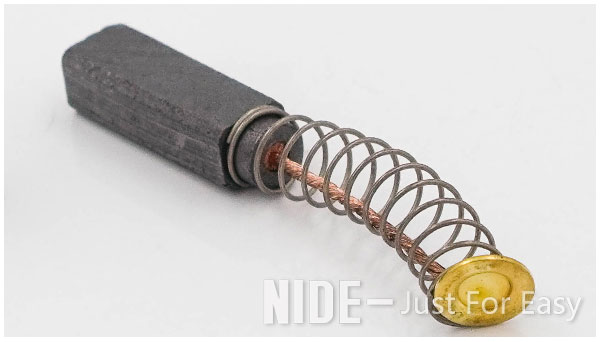

Copper graphite carbon brush for Electric Angle Grinder motor

Model number:NDPJ-TS-75

Introduction:Our carbon brush is suitable for Car motorcycle carbon brush,Power tool carbon brushm, Noil carbon brush, DC motor carbon brush, AC motor carbon brush ,generator carbon brush, etc.

- Specification

China Power Tools copper carbon graphite brush for Electric Angle Grinder motor

NIDE can produce different types of carbon brushes and graphite products. Our carbon brushes are widely used in automobile starters, car alternator , power tool motor, machinery, molds, metallurgy, petroleum, chemical, textile, electromechanical, universal motor, DC motor, diamond tools and other industries. The company is backed by first-class production technology and advanced equipment, with various professional and technical personnel, senior engineers and experienced production workers. We can provide customers with various types of carbon brush customization and processing to meet customer needs.

We fully implement the ISO9001 quality certification, and at the same time introduce advanced foreign production technology and formula, the products produced are widely used in many fields, and are sold well in domestic and foreign markets, and are exported to North America, Southeast Asia, Europe and other regions.

We manufacture and design many patterns, grades and types of carbon brushes ensuring the correct carbon brush is available to meet your requirements for your motors or generators, and advice on carbon brush grade selection is given by our technical experts. The benefits to our customers include carbon brushes that can increase uptime and reduce maintenance costs by improving machine reliability and availability.

We have a strict control system of our product. Our traceability system focus on the inspection not only in the production process but also with raw material(like graphite powder, copper powder) incoming test.Technical requirement

Material Model Resistance Bulk density Rated current density Rockwell hardness loading Carbon black D308 40±40% 1.62±10% 10 86(-45%~+25%) 100KG D374L 50±50% 1.71±10% 12 82(-50%~+67%) 100KG D374B 57±57% 1.57±10% 12 83(-35%~+20%) 100KG Advantage: high strength, low bulk density, good rectification performance Application of D308: suitable for mirco DC motor, like voltage regulator Application of D374L: suitable for small high speed series excited motor Application of D374B: suitable for traction motor, generator motor, exciting dynamo motor or DC motor which commutator cannot be used Carbon brush features:

Our electrical carbon brushes are made from low friction conductive carbon materials, Selecting the correct grade carbon brush is important for commutator performance, maximum brush life, and high motor performance.

Our carbon brushes are consistent reliable electrical performance and low wear rates on motors and generators.

Good quality

Small spark

Low noise

Long duration

Good lubrication performance

Good electric conductivity

Carbon brush Application:

Our carbon brush is suitable for Car motorcycle carbon brush,Power tool carbon brushm, Noil carbon brush, DC motor carbon brush, AC motor carbon brush ,generator carbon brush, etc. They are used in steel processing, mining, power generation, traction and a wide range of general industrial applications all over the world.

Carbon brush importance:

1. The external current (excitation current) is added to the rolling rotor through the carbon brush (input current)

2. Bring the static charge on the large shaft through the carbon brush to the earth (earth carbon brush) (output current)

3. Lead the main shaft (ground) to the protective device for the rotor grounding protection and the positive and negative voltage of the rotor

4. Change the current direction (in commutator motor, the brush also has a commutation function)

Information needed for carbon brush inquiry:

It will be better if customer could send us detailed drawing including below information.

1. Carbon brush dimension: length, width, height, lead wire length

2. Carbon brush material:

3. Carbon brush voltage and current requirement.

4. Carbon brush applications

5. Required quantity

6. Other technical requirement.If possible, it will better if customer could send us samples.

We have a wide range of carbon brush. Our carbon brush has a wide application, such as automotive industry, household appliances, hammers, planers and etc. We directly supply our carbon brushes to many countries. We could customize carbon brush for our customer.

About Motor component and accessories

NIDE can supply the full range of electric motor components such as commutator, ball bearing, thermal protector, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English