Washing Machine Motor Automatic stator Winding Machine

Model number:RXL1-160A

Introduction:The automatic stator winding machine is especially suitable for stators with high slot fill factor and small slot opening.Mainly used in the field of household appliances, such as washing machine, fan, refrigerator, air conditioner, recorder, video recorder, video player, vacuum cleaner, camera, hair dryer, electric shaver, etc.

- Specification

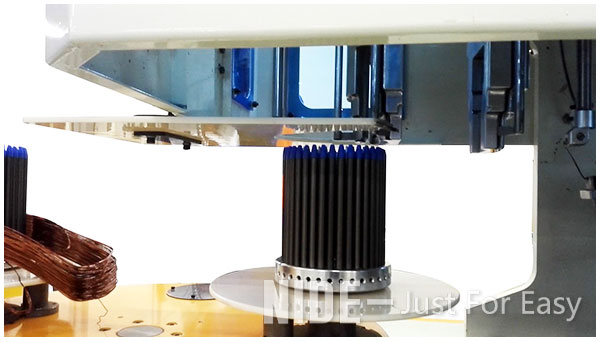

2 Winding Heads Electrical Motor Automatic Stator Winding Machine for Washing Machine

The automatic stator winding machine has 2 winding heads working stations with turntable. It can wind coils directly and orderly into transfer cups. Especially suitable for stators with high slot fill factor and small slot opening. It's easier for operators to insert the coils of stators with high slot fill factor and small slot opening width. So the automatic stator winding machine can save labor effectively.

(1) Technical Parameters

Product name: Automatic washing machine Electrical Motor stator winding machine

Winding head: 2pc

Wire diameter: 0.17~1.2mm

Max stack OD: 160mm

Max stack height: 100mm

Winding speed: ≤2000RPM

Flier track: ¢400mm

Transfer number: 2~6section

Air pressure: 0.5mpa

Voltage : 380V/50/60HZ

Power supply: 7KW

Weight: about 1500kg

Dimension: L1800*W1100*2200mm

(2) Main Features

1. Automatic put the coil into transfer former orderly; Able to exactly wind coils onto the forklike flywheel and easily transfer the coil to coil inserter, with high efficiency and great inserting winding effect.

2. Double winding heads automatic stator winding machine; the electric motor coil winding machine is a double-station automatic vertical winding machine, The turntable is two stations structure.

3. The stator winding machine adopts servo system to rotate and index transfer form. Winding mode such as automatic skip, automatic cutting and automatic indexing can be finished successively at one time;

4. Each coil winding machine has one set winding tooling and three vertical winding forms.

5. Especially suitable for stators with high slot fill factor and small slot opening;

6. The whole set of tooling can be changed, and it takes about 15min.

7. Main spindle is controlled by servo motor. The coil turn number accuracy is ±1 turn.

8. PLC can set Parameters, turn number, winding speed, winding tension, tooling sunk height, tooling sunk speed and winding direction is adjustable.

9. Obtain continuous or discontinuous winding way and meets the 2 poles, 4 poles and 6 poles coils winding;

10. X and Y spindle of wire hooker and wire cutter adopts servo system. It can adjust the length of bridge wire and lead wire.

11. Tooling sunk adopts servo system. The max segment number of tooling sunk is 6.

12. The stator winding machine can wind single or multiple wires simultaneously.

13. And it is endowed with the display function of dynamic turns, actual turns, set turns, failure causes and position self-check.

14. Free of enamel damage and wire snap. Once the copper wire is run out, machine will automatically stop.

15. The automatic coil winding Machine has no distinct vibration and noise.

16. The stator winding machine saves labor and has high efficiency.

(3) Application

The automatic stator winding machine is suitable single phase induction motor and three phase motor manufacturing ,and mainly used in the field of household appliances, such as washing machine, fan, refrigerator, air conditioner, recorder, video recorder, video player, vacuum cleaner, camera, hair dryer, electric shaver, etc.

(4) Picture show

(5) The washing machine Electrical Motor Stator Winding Machine video

(6) Maintenance

1. Before running machine, check the automatic stator winding machine mechanical parts, electric, hydraulic parts, lubricating parts, and check if the fastener loosen, running parts make any noise and electric parts running normally or not. After checking ok, machine can be running.

2. After stator winding machine working, clear the dust and reset the machine.

3. Clear the electric elements every three month.

4. Check if there is water in the filter of hydraulic parts. If yes, please drain away water on time.

5. Check if there is oil on the lubricator of hydraulic parts. If no oil, please add oil on time.

6. Check if lubricating status of guide mechanism. If no lubricating oil, please add lubricating oil on time.

7. Please check the magnet valve screw and pipe joint every three month.

8. Please check the filter and air filter every two month.

9. Please check the air pressure very year once.

10. Add mechanical oil

About Motor stator manufacturing

Motor stator manufacturing production assembly line including paper inserting machine, coil winding machine, coil winding inserting machine, lacing machine, forming machine and testing machine.NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

About NIDE

Nide is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.We can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.We also provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machine's application

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English