Universal Series Motor Stator Winding

and Assembly Line

The Fully Automatic Universal Motor Stator Winding and Assembly Line is specifically

designed for efficient, high-speed production of universal electric motor stators, including

applications such as:

This automated production line covers the full stator winding and assembly process, including

coil winding, wire insertion, forming, and positioning—all controlled through a PLC-based

system with a user-friendly HMI touchscreen interface for simple operation and fast product switching.

Key Features:

High-Speed Precision Winding

Efficient and accurate coil winding with programmable settings for different winding patterns

and stator sizes.

Fully Programmable & Flexible

The line supports flexible tooling changes, allowing fast switching between different stator

designs or motor models.

Advanced Automation Technology

Reduces labor intensity while maintaining consistency and quality throughout the stator

manufacturing process.

Compact & Modular Design

Occupies minimal floor space and integrates seamlessly into both small-scale and large-scale

production lines.

User-Friendly Operation

Easy setup and intuitive control interface ensure fast startup, ideal for varying production batches.

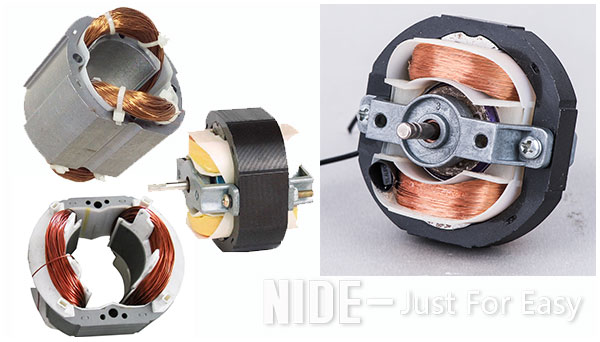

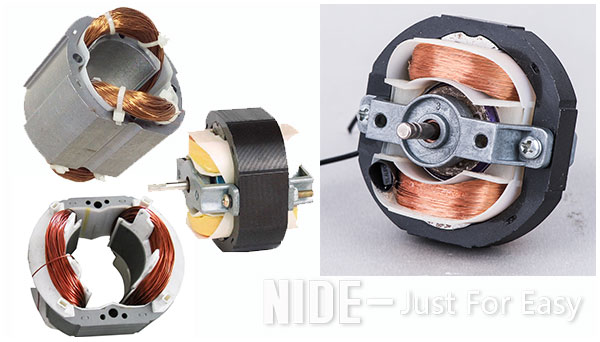

Structural Design & Working Principle

The stator lamination used in universal motors typically features two poles connected by a

ring-shaped flux return path, which defines the outer diameter of the stator core. Each pole has a

pole face forming a central rotor space (inner diameter) for rotor placement. A neck portion connects

the poles to the ring, forming a cavity for coil winding around the pole. This design ensures that the

winding process does not interfere with the rotor clearance, allowing a compact and efficient magnetic

circuit.

This winding line is engineered to adapt to such structural designs and perform coil winding precisely

around each pole using automatic positioning and high-speed wire feeding.

Applications

Stator production for universal motors

Household appliance motor manufacturing

Compact motor coil winding automation

Power tool stator assembly

High-speed stator production systems

About NIDE - Your Reliable Partner in Motor Manufacturing Equipment

NIDE Group specializes in the R&D and manufacturing of motor production machinery. We offer a full range

of solutions including standalone machines, fully automatic production lines for armature and stator, and

complete motor assembly lines. With over a decade of experience, we support clients with high-efficiency

equipment and tailored automation solutions for various motor types.

Our product portfolio also includes motor components such as commutators, ball bearings, carbon brushes,

insulation paper, shafts, magnets, cooling fans, and motor covers. In addition, NIDE provides technical consulting,

project design, and turnkey services to help clients optimize their motor manufacturing processes.

Machines Application

NIDE machines are widely used in the production of various motor types, including:

AC motors / DC motors / BLDC motors / universal motors / induction motors

Single-phase and three-phase motors

Common application fields:

Household appliances: washing machines, air conditioners, vacuum cleaners, electric mixers,

electric shavers, hair dryers, electric toothbrushes

Industrial equipment: pumps, compressors, power tools, fans, coolers

Automotive: electric vehicles, hub motors, alternators

NIDE helps manufacturers build efficient, automated motor production lines for both high-volume

and customized projects. More information please check our New Website: www.nidegroup.com.

Global Service & Support

NIDE offers global installation support, training, and after-sales services. Our engineering team ensures

smooth machine integration and continuous production performance. Contact us for technical consultation

for guidance on equipment selection.

Contact Us

marketing8@nide-group.com (Head of Electric Machinery and Equipment)

emarketing@nide-group.com (Head of Motor Parts)

SNS

中文版

中文版 English

English