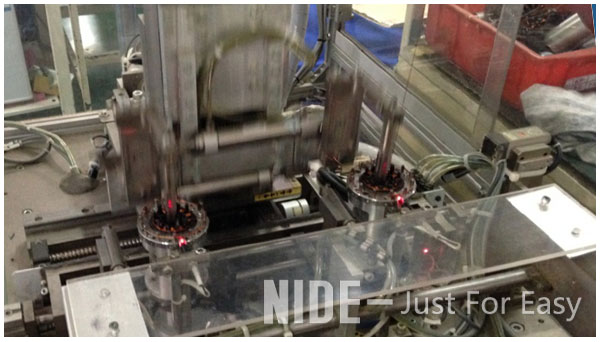

Double working stations stator needle winding machine

Model number:ND-DDR-IV-B

Introduction:The stator needle winding machine Adopts Double station, auto winding, auto tapping, auto wire clamping, auto wire cutting, auto wire arraying and auto wire acrossing.

- Specification

Technical Parameters of Sator Needle winding machine

(1) Main technical parameter:

1.Stator O.D:Φ30-Φ150mm

2.Stator ID: Φ10-100mm

3.Stack length: 5-125mm

3.Wire diameter:Φ0.2-Φ1.50mm,select suitable tensioner as per actual wire diameter.

4.Pole no.: could be customized

5.Winding speed:400-800rpm (adjustable)

6.Tensioner: magnetic tensioner

(2)Description:

1.Double station, auto winding, auto tapping, auto wire clamping, auto wire cutting, auto wire arraying and auto wire acrossing.

2.one winding nozzle at each winding station, wind the stator one slot by one slot, the stator is requested to have plastic bobbin

Manual stator loading/unloading, stator clamping is finished by pneumatic chuck.

3.Main controller adopts PLC, AC servo system and robot motion control system, to complete winding, arraying,

auto indexing and wire cutting.

4.Adopt switch power source and touch screen to display and

set winding parameter.Adopt cylinder and Korea SYC magnetic valve to complete to assist winding action.

5.Winding motor A and B axis is 4.5kw AC servo motor left-right rotation indexing,

winding motor at Z axis up-down movement is 3.0kw AC servo motor,

left-right horizontal movement at X axis is 750w AC servo motor,

front-back horizontal movement and wire arraying Y axis motor is 750W AC servo motor.

6.Adopts screw rod and ball rail, precision degree is H(error precision is 0.01~0.02mm),

About Motor stator manufacturing

Motor stator manufacturing production assembly line including paper inserting machine, coil winding machine, coil winding inserting machine, lacing machine, forming machine and testing machine.NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

About NIDE

Nide is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.We can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.We also provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machine's application

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English