Rotor automatic aluminum die-casting machine

Model number:XS-100T-K

Introduction:This rotor casting machine adopts a vertical structure. Machine is under control of PLC.

- Specification

Rotor automatic aluminum die-casting machine

(1) Technical requirement

1.The die-casting machine is controlled by PLC.

2. Injection cylinder has three different injecting mode, slow injecting, fast injecting and secondary injecting. The injecting flow of fast injecting can be manually adjusted.

3. Machine is equipped with auto feeding device, cutting device and mold unloading device.

4.This machine has protector doors on all sides. It is pneumatic protector door in the fore-and-aft direction.

5. Machine is equipped with water cooling system.

6. Each machine is equipped with two pieces of stuff canister, which is customized.

(2) Parameter

Specification

100T

mold clamping force

1000Kn

Oil cylinder travel

480mm

Max opening

800mm

Injecting force

400Kn

injection cylinder travel

180mm

Working station area

680x820mm

injection chamber OD

60—120 mm

Motor power

15—4 KW

Oil pump model number

CY—63

(3) Machine feature

1.Rapid mould closing

2. With feeding, cutting and mold unloading device

3. It can once make four products if the rotor outside diameter is within 40mm.

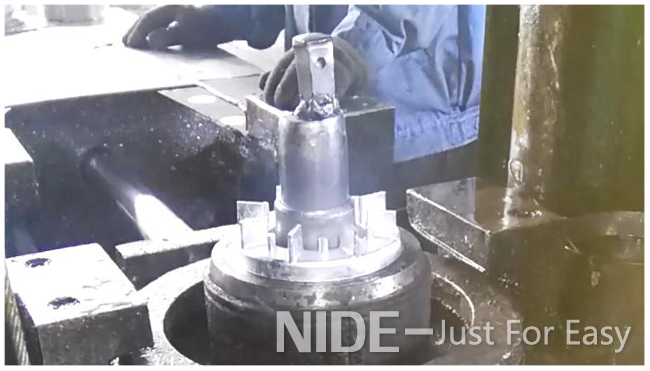

(4)alumimum die casting machine picture show

About Motor armature manufacturing

Motor armature / rotor manufacturing production assembly line including: shaft pressing machine, end cover pressing machine, commutator pressing machine, armature insulation paper inserting machine, armature winding machine, commutator hot stacking machine, armature wedge inserting machine and armature testing machine, ball bearing inserting machine, and worm shaft inserting, NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

About NIDE

Nide is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.We can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.We also provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machine's application

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English