- Specification

This type of rotor winding machine adopts international advanced technology that use AC servo for winding and indexing. Also, this series of armature

winding machine uses colorful LCD which is easy for users to change the parameter, and improve the efficiency largely. It is suitable for small wire diamter winding. The coil winding machine is a good choice for motor manufacturer.

(1)Techinical parameter:Item Specification Wire diameter 0.08~0.30mm (Mechanical type) 0.16~0.55mm (Hysteresis) Winding slots Odd/even number Commutator diameter 8~40mm Armature diameter 20~60mm Armature stack length 10~60mm Winding motor speed 0~3000 rpm Control system Mitsubishi PLC control Air supply pressure 5~7 Kg/cm2 Voltage AC220V 50/60Hz Weight 1180Kg Dimension 1800(length)X800(width)X1500(height)mm (2) Machine Feature:

Three winding mode: single slot-single hook, single slot-double hook and double layer winding. It could do twice winding in one slot, four times winding in the two adjacent slots. It has automatic treatment for wire broken, 2 settable sequences is: winding before broken, or broken before winding.

Production parameter for 100nos armatures could be stored

Display parameter, including shift output, total output, consuming time, etc.

Automatic alarm if any abnormal condition occurs

Single action, automatic and stepping operation could be switched

Steady fixture, up and bottom protective tooling and protective wire hooking device

Loading mode: cylinder feeding armature automatically, get out finished armatures manually

(3)Common malfunction of this machine

Sometimes, there is servo alarm displayed on the touchscreen. In this case, there will be error code displayed on the servo driver(at the backside of machine), you could identify the problem according to the error code. The most common malfunction is the encoder cable which connects the servo driver and servo motor is loose, just need remove and reinsert the encoder cable again, problem will be solved.

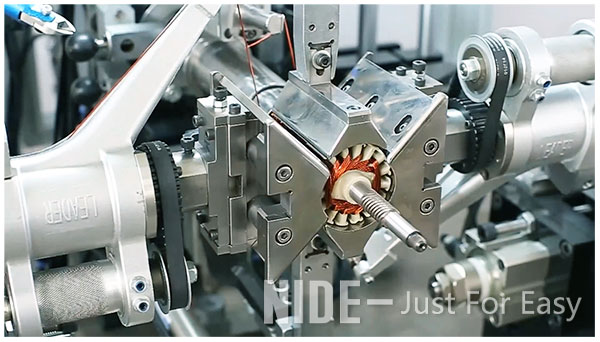

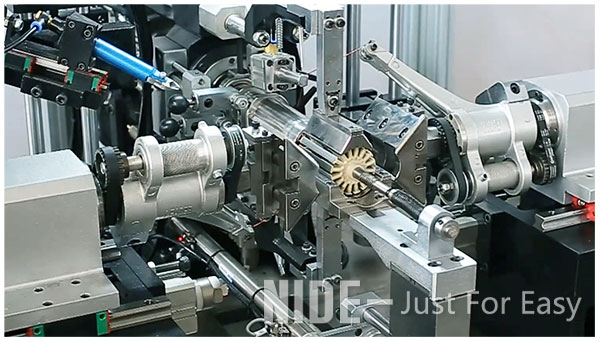

(4)The rotor winding maching picture show

1. the coil winding machine Surface structure

2.The rotor winding machine Internal structure

3.The rotor windingn machine parts display

Automatic vacuum cleaner rotor winding machine video

About Motor armature manufacturing

Motor armature / rotor manufacturing production assembly line including: shaft pressing machine, end cover pressing machine, commutator pressing machine, armature insulation paper inserting machine, armature winding machine, commutator hot stacking machine, armature wedge inserting machine and armature testing machine, ball bearing inserting machine, and worm shaft inserting, NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

About NIDE

Nide is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.We can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.We also provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machine's application

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English