Semi automatic motor Rotor assembly line

Model number:ND-ZZX-1

Introduction::This rotor assembly line can achieve fully automation. All the machines are connected with each other by conveyor.

- Specification

This rotor manufacturing assembly line including: shaft pressing machine, end cover pressing machine, commutator pressing machine, armature insulation paper inserting machine, armature winding machine, commutator hot stacking machine, armature wedge inserting machine and armature testing machine, ball bearing inserting machine, and worm shaft inserting, All the process will be done by machine. Operator only needs to do loading and unloading.

Process:

Shaft press---end cover press---commutator press----armature insulation paper inserting---armature winding—commutator welding----wedge inserting— armature testing---ball bearing inserting,

Shaft pressing machine

Shaft Pressing machine is used to insert shaft into lamination. User only need to load lamination and shaft. Then machine will do inserting automatically.

End cover machine

After shaft inserted, assembly line will transfer the rotor to next station. And it will do end cover inserting.

It adopts vibration boult feeding method.

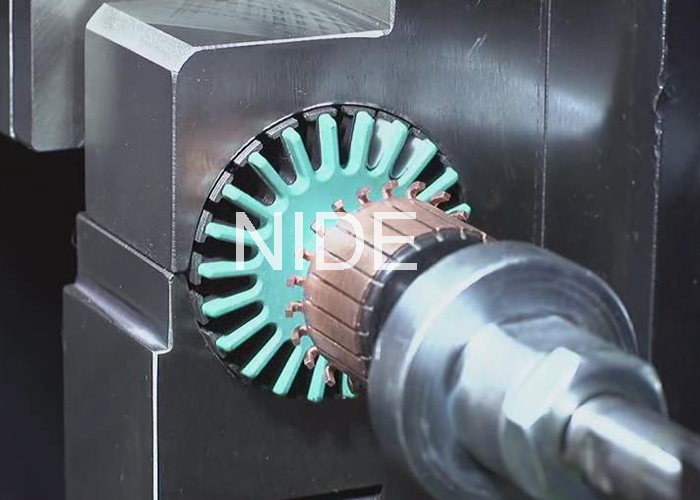

Commutator Pressing machine

This machine is used for pressing commutator onto the shaft. Machine can automatic feeding commutator and armature core. This machine can also be connected to a production line to achieve mass production requirement.

Insluation paper inserting machine

This machine is used to inserting paper into rotor slot. The insulation material can be as per customer's requirement, DMD, DM, polyester film are all can be used in this machine.

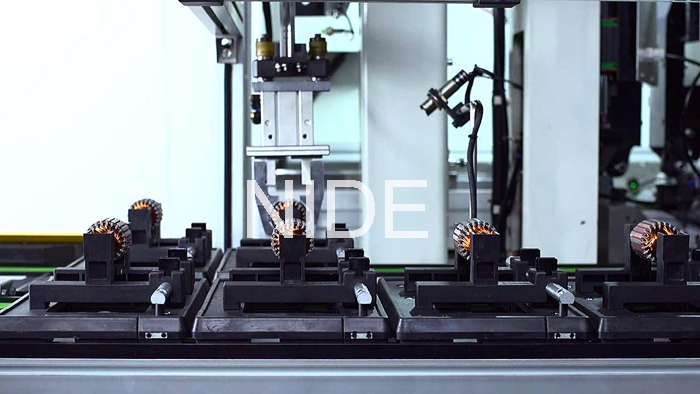

Rotor winding machine

After doing paper inserting machine, mechanical arm and converyor will carry the rotor the rotor winding machine position. The machine is equipped with touch screen and PLC, winding parameter could be set and modified on the screen.

Commutator welding machine

It can weld both riser and hook type commutators. There are four power control method, namely secondary constant current, secondary constant voltage secondary constant frequency. This machine is applied to DC motor and universal motor. It is controlled by PCL, all the data setting can be done on the touch screen.

Wedge inserting machine

The wedge material can be as per customer's requirement, DMD, DM, polyester film are all can be used in this machine.

Commutator turning machine

After wedge inserting, converyor will tranfer rotor to the turning position. There will be two turning working station. t greatly improves the working effiency. After turing, there is a bur-removing machine to clean the commutator.

Rotor testing machine

It is suitable for testing less than 72 segments Testing items could be screened.Testing data saved automatically, and could be traced and printed at any time.

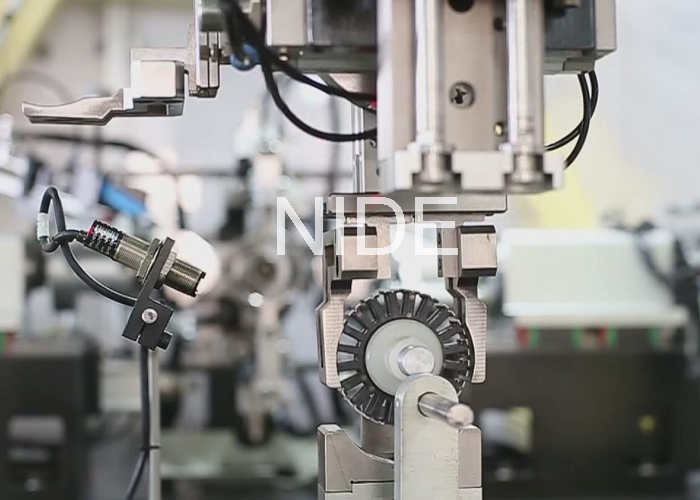

Ball bearing inserting machine

This machine can automatically insert ball bearing into the rotor. The inserting position is as per customer's requirement. Mechanical arm will automatically pick up ball bearing. The conveyor will transfer the rotor to the standby position.

Worm shaft inserting machine

This machine can automatically insert worm shaft into the rotor. Mechanical arm will automatically pick up worm shaft. The conveyor will transfer the rotor to the standby position.

The rotor Production assembly Line working video

About Motor armature manufacturing

Motor armature / rotor manufacturing production assembly line including: shaft pressing machine, end cover pressing machine, commutator pressing machine, armature insulation paper inserting machine, armature winding machine, commutator hot stacking machine, armature wedge inserting machine and armature testing machine, ball bearing inserting machine, and worm shaft inserting, NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

About NIDE

Nide is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.We can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.We also provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machine's application

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English