Generator Armature Automatic Balancing Machine

Model number:ND-BFZSZ-5L-A

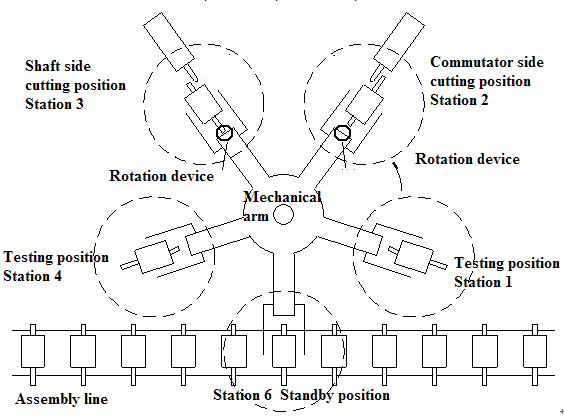

Introduction:This balancing machine is using weight remove method. The are five working stations.

- Specification

(1) Machine function and characteristic

For this type of Five station Armature Balancing Machine, armature does not need to mark, directly put on the conveyor, there are 5 working stations: loading and unloading station, initial measuring station, left side cutting station, right side cutting station and remeasuring station. High efficiency and precision.PLC controlled, all the data can be set on the touch screen.

Machine consist by idle station (station0), initial test station (station1), commutator end processing work bench (station 2), shaft end processing work bench (station3) and retest station (station 4) such five station in total. Besides, it is also include five machine hands,transportation line,drilling main shaft and dividing devices.

The procedure of single circle runs as following:

Transportation line take generator armature to idle station (station 0);

Machine hands transport it from idle to initial test station (station 1) to measuring original unbalance mass, positioning the right place and depth before process.

Machine hands move armature to next station (station 2) in order to process imbalance amount of commutator end.

Machine hands move generator armature to next station (station 3) in order to process imbalance amount of shaft end. Before that, machine hand will turn 180 degrees of armature to lead shaft end out towards.

Machine hands move product to retest station (station 4), measuring the permissible residual unbalance. Before that, machine hand will turn 180 degrees of armature to lead shaft end inner towards.

Machine hands move product back to original station (station 0), while the armature is qualified after test, machine will pick up next one from idle station to start another round processing, good one will come back to transportation line. If the result is not within permissible residual unbalance, system command the machine come back to the first stage and restart a copy. There are five stations in this machine, so it is possible to process five pieces in the mean time.

Production Cycle time:

The way of process is radial drilling method, use F6~ 8 driller; the cycle time 25 to 30 seconds per unit in condition of initial unbalance amount within 300gmm.

(2)Technical Parameter:

Armature Diameter

Stack height: 30-100mm

Armature diameter: Φ80~115

Balancing speed

1500-2200rpm

Milling method

Drilling

Power

AC380V

Air supply

0.4~0.6Mpa

Cycle time

25-30s

Residual unbalance

eccentricity

Better than the national standard for Grade 6.3

Volume

(length x width x height)

2200 x 1700 x 1800 mm

(3) Application

The automatic motor rotor balancing machine is suitable for generator.

About Motor armature manufacturing

Motor armature / rotor manufacturing production assembly line including: shaft pressing machine, end cover pressing machine, commutator pressing machine, armature insulation paper inserting machine, armature winding machine, commutator hot stacking machine, armature wedge inserting machine and armature testing machine, ball bearing inserting machine, and worm shaft inserting, NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

About NIDE

Nide is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.We can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.We also provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machine's application

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English