Types of Alternator Motors

Different generator motors are used based on power demands:

Brushless Alternator Motors: Low maintenance and highly efficient.

12-Lead Motors: Provide adaptable voltage configurations for various applications.

Industrial-Grade Alternator Motors: Designed for high-output and long-term operation.

When selecting a motor for a generator system, consider:

Power and Voltage Requirements: Ensure compatibility with your generator setup.

Load Capacity: The ability to handle fluctuating energy demands.

Energy Efficiency Ratings: Reduce operational costs and improve performance.

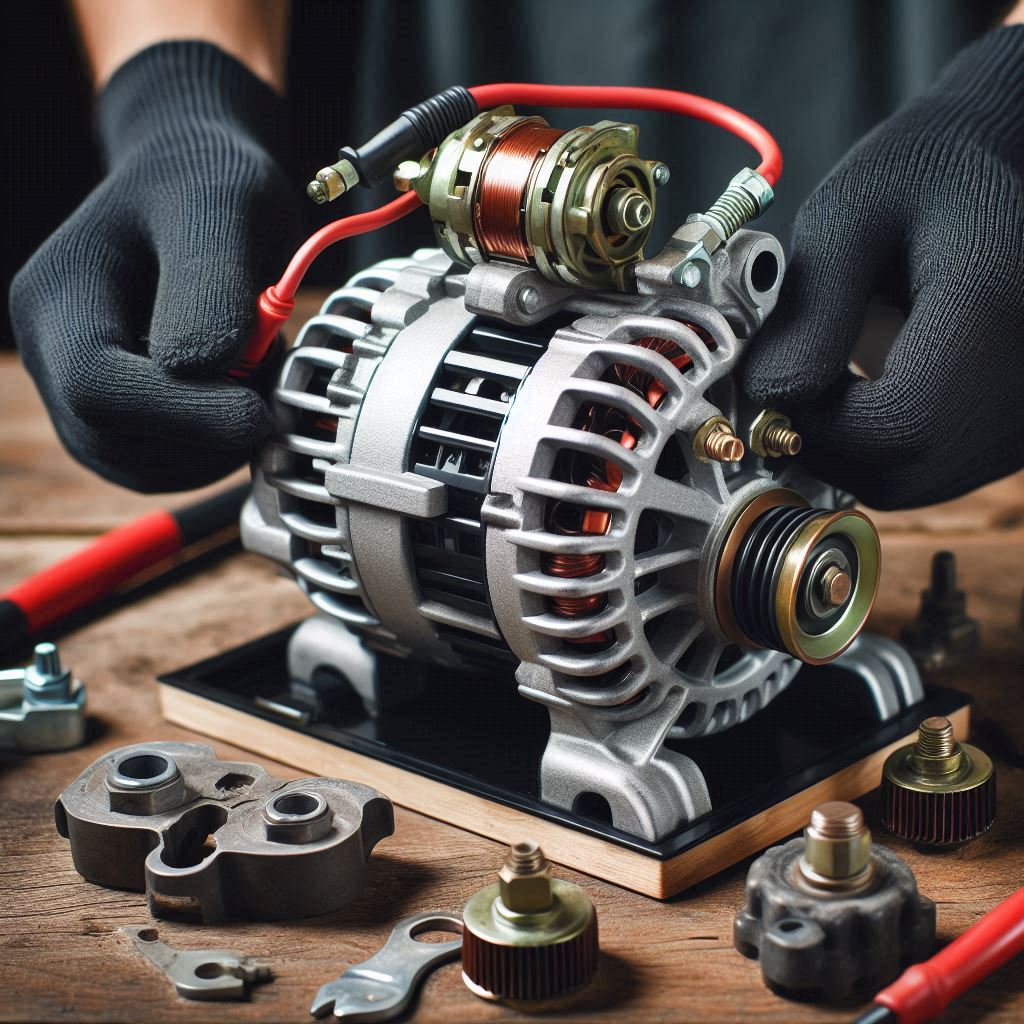

How to Maintain an Alternator Motor

To extend its lifespan and efficiency, follow these maintenance best practices:

Routine Inspections: Check for overheating, wiring issues, and general wear.

Cooling System Maintenance: Prevent excessive heat buildup.

Lubrication of Bearings: Reduce friction and extend motor life.

Regular Load Testing: Ensure the motor operates under real-world conditions.

Voltage and Frequency Monitoring: Maintain a stable electrical output.

Proper upkeep of an alternator-driven motor ensures it delivers optimal power efficiency

in various industrial and backup power applications. Adding a voltage regulator can further

stabilize output, enhancing system reliability.

By selecting and maintaining the right generator motor, businesses and individuals can improve

energy efficiency and ensure uninterrupted electrical supply.

中文版

中文版 English

English