How Does an Alternator Generator Work?

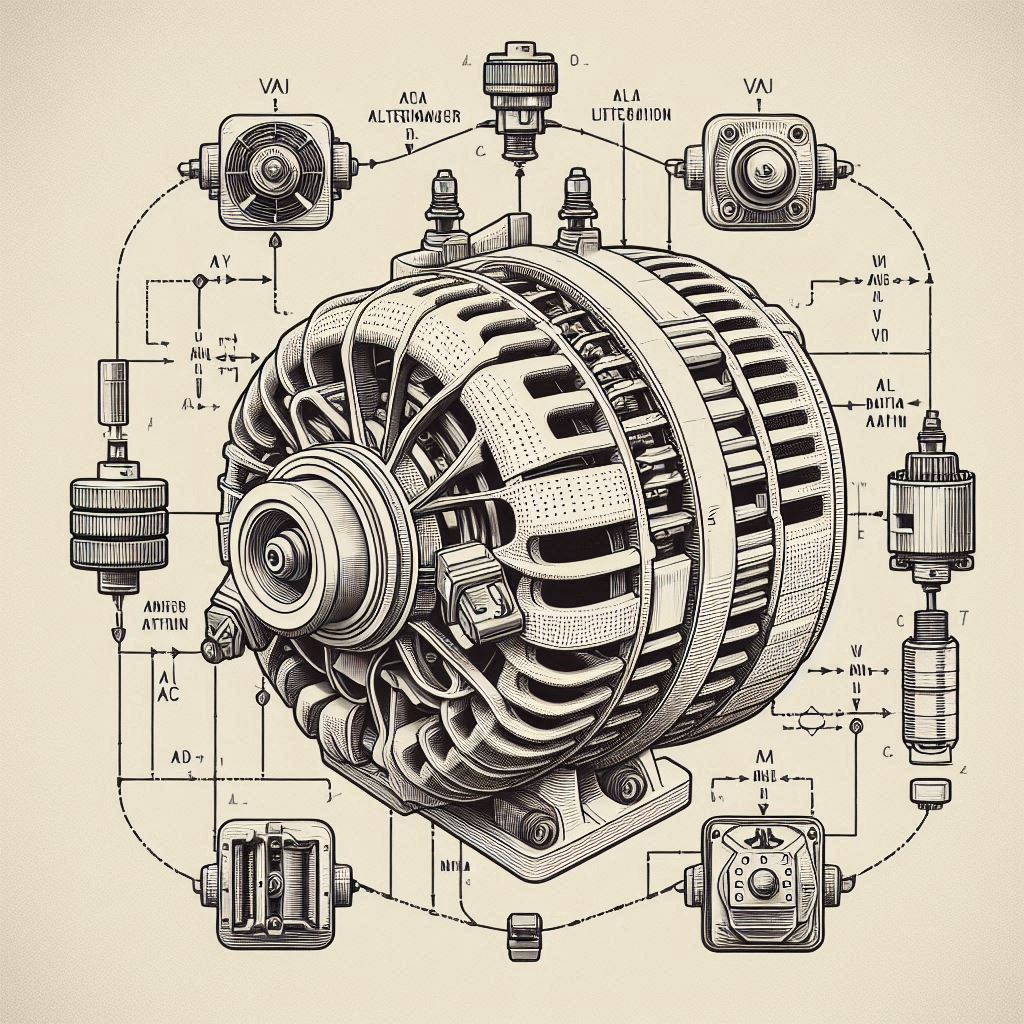

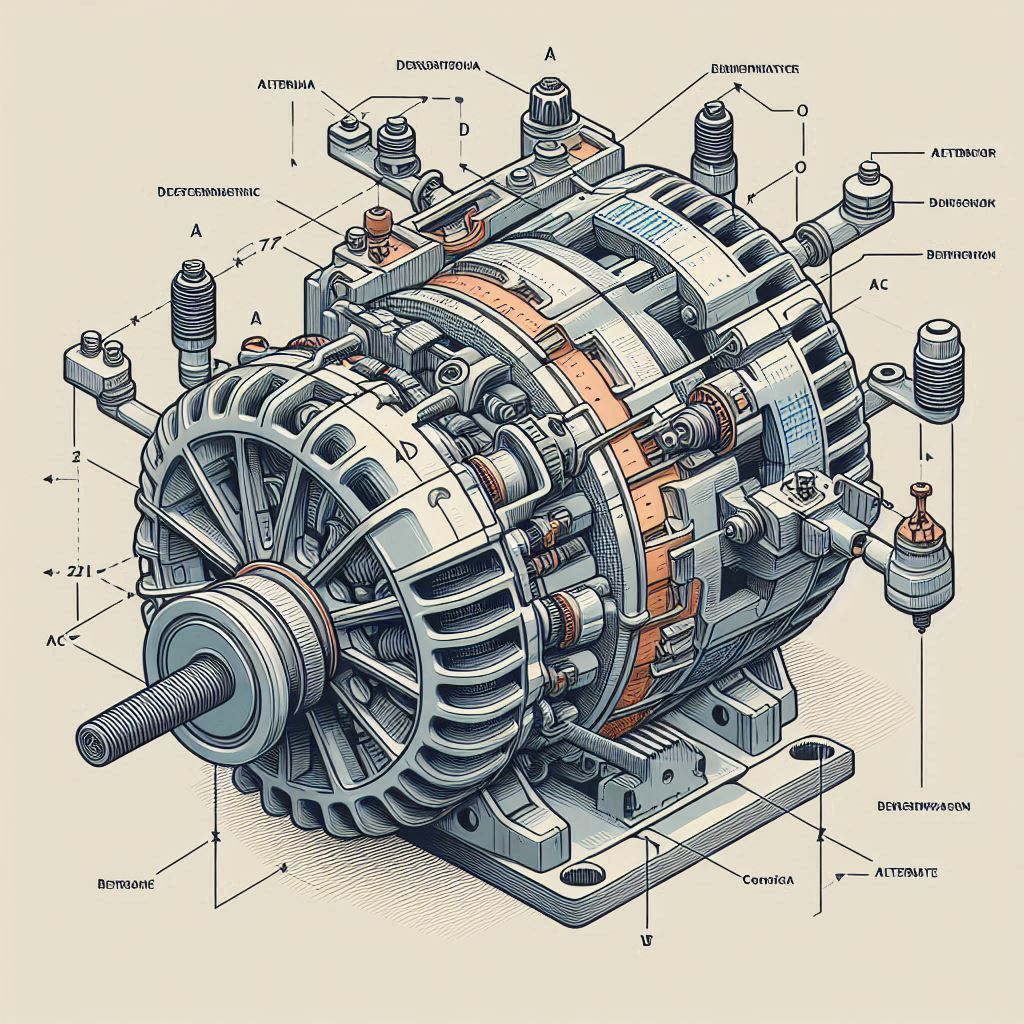

This type of electrical generator functions based on electromagnetic induction.

It consists of two main parts:

Rotor: The moving component, driven by an external power source like an

engine or turbine.

Stator: A stationary coil that generates AC electricity.

As the rotor spins, it produces a magnetic field, inducing alternating current (AC)

in the stator windings. They convert the output to usable electrical power, making

these devices essential for various applications.

How to Choose the Right Alternator Generator

Selecting the right model requires considering several key factors:

Power Output: Match the generator's capacity with your energy needs.

Voltage and Frequency: Ensure compatibility with your electrical system.

Environmental Factors: Heat, humidity, and altitude affect performance.

Fuel Efficiency and Durability: Opt for a model with low operational costs

and high reliability.

Common Applications

These electromechanical generators are widely used in:

Manufacturing Facilities: Powering heavy machinery.

Transportation: Supporting marine, aviation, and automotive electrical systems.

Renewable Energy Solutions: Integral to wind and hydroelectric power stations.

Backup Power Sources: Providing emergency electricity for homes and businesses.

Regular maintenance ensures long-term efficiency, making these AC power generators

a critical investment for any energy system.

中文版

中文版 English

English