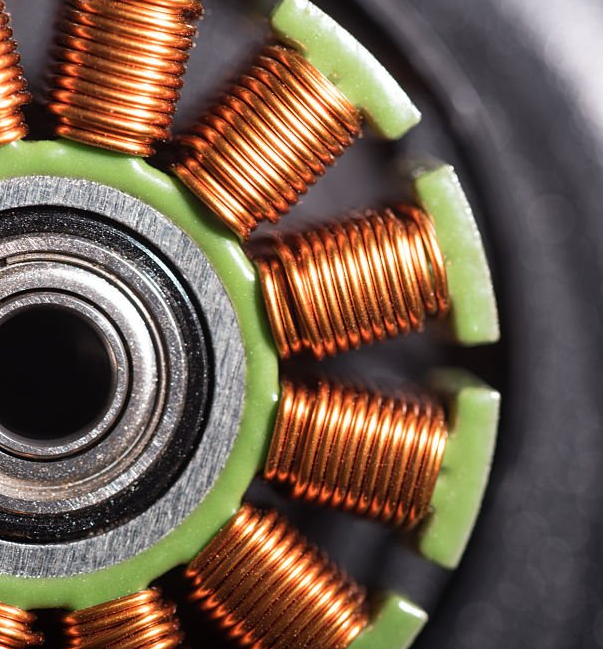

What is motor winding

The motor winding is the coiling of the conductor between the housing and the rotor. The conductor

is a high-conductivity wire that can be wound in different thicknesses.

The tighter the windings can be, the smaller the diameter of the wire. This changes the operation of the

motor significantly because it changes the magnetic field created when current flows through motor winding.

Influence of operating behavior on the functioning of a system

The motor winding depends on the thickness of the wires and their intensity. The more motor windings

can be achieved with thinner wires. This can have several effects:

With each winding, the strength of the magnetic field increases.

The torque increases as a result.

The overall electromagnetic force of the system increases.

The counter voltage increases and the operating voltage is reduced as soon as speedsincrease. The

properties of the motor windings are already a hint to their application. The magnetic field strength

is high and can generate a high torque at low speeds. The torque decreases as the speed increases

due to the decreasing counter voltage.

Electrical resistance also causes greater heat loss. This calls for appropriate cooling.

Applications that resulted

Applications resulting from motor winding advancements span across various industries, enhancing efficiency

and performance in numerous fields. In industrial automation, precisely wound motors power conveyor belts,

robotic arms, and CNC machines, ensure smooth and reliable operation. The transportation sector benefits

from electric vehicle (EV) motors, where optimized winding techniques improve energy efficiency and torque output.

HVAC systems rely on well-designed motor windings for fans, compressors, and pumps to maintain energy

efficiency in heating and cooling applications. Renewable energy solutions, such as wind turbines and

hydroelectric generators, depend on advanced motor winding designs to maximize power generation

and durability. Additionally, household appliances, from washing machines to refrigerators, utilize finely

wound motors to deliver consistent performance with minimal energy consumption.

You can read more about it here:

The motor winding is the type of electrical conductor winding that generates a magnetic field to drive the

motor's rotors.

The design determines torque, electromagnetic force, electrical resistance and the application. The more

tightly wound the motor, the greater the torque and force produced. Resistance and waste heat will also

increase at higher speeds. So, the motor windings can be adapted to each application. Electric motors

from NIDE areperfectly suited to any type of drive in the industry.

中文版

中文版 English

English