Hairpin Stator Production Process-Hairpin Motor Technology

The hairpin technology is already widely used in generators and currently shows a strong trend towards EV car (electric vehicle) motors in the automotive industry.In contrast to the classic processes, the hairpin technology is a forming based assembly process.It is suitable for stator winding of synchronous and asynchronous motors with distributed winding.

The advantage of the hairpin stator is high economic efficiency, High automation capacity, High scalability, Reduced production costs.

The hairpin technology uses massive copper wires (usually flat copper wires)which are inserted in the stator slots of the laminated sheet metal package. The electrical slot filling factor of hairpin stators is very high (approx. 73%) due to the rectangular cross section and the small number of windings and is thus considerably higher than the slot filling factor of conventional stators (45-50%, depending on the insulation thickness).The U-shaped hairpins thus replace the classic winding processes such as needle winding, flyer winding and the pull-in technique.

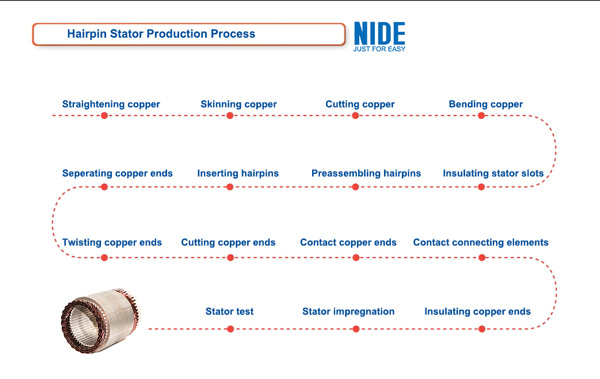

Hairpin Stator Production Process

NIDE Group is able to provide turn-key service of EV motor production line with hairpin technology. The turn-key service includes making drawing, production process, factory layout, training your operator, making samples till mass production, etc. We have delivered high quality production lines for the most expressive companies worldwide.

中文版

中文版 English

English