fan motor coil winding machine from China manufacturing

Model number:RX2-250B

Introduction:The semi automatic motor coil winding machine is suitable for fan motor, table fan motor ,washing machine motor and various small motors, square, round and multi-layer motor coil.

- Specification

semi automatic motor winding machine for table fan motor and washing machine motor from china motor manufacturing supplier

1.Motor coil winding machine application

The semi automatic motor coil winding machine is suitable for fan motor, table fan motor ,washing machine motor and various small motors, square, round and multi-layer motor coil.

As an excellent manufacturer and supplier of motor manufacturing machines, Nide Mechanical can provide professional motor manufacturing equipment and motor manufacturing technology consulting services.

2. Motor coil winding machine technical data:

Product name: semi automatic motor coil winding machine for fan motor and washing machine motor Machine color: RAL7035(or as per customer’s requirement) Diameter of Wire: 0.5-1.5mm; Swing diameter: 500mm; Winding former Diameter: Max.350mm Turn No. accuracy: 0.2%; Wire feeding head: 1-4 pc Transfer distance: 170-300mm Array wire number: 1-12; Working speed(no-load): 0-800(according to different diameter wire,

the speed is stepless adjustable,no obvious vibration or noise;)

Max rotation speed: 1600R.P.M Machine productivity: around 1000 pcs/8 hours Power / Input: 220V/50Hz Air pressure: 0.5-0.8MPa Power: 0.75KW Main motor power: 2.2KW-6P; Frequency converter: 2.2KW; Effective length of the square spindle: 520mm.; Dimension of square spindle: 20*20*625mm; Dimension: 1550mm × 1250mm × 1450mm Weight: ≈ 850kg

3. Motor coil winding machine characteristicsAutomatic slotting, automatic tapping,

the operator only needs to put in and pick up the winding mold, and takes the wound coils out of the mold .

with two winding square axle spindle;

low vibration and low noise ;

No broken or enamel damage for the wire;

Main electric parts and bearing adapts high quality motor parts;

The turn No., wire dia., wire arraying width, transfer distance, winding direction and wire arraying direction are all settable on the controller;

Wire array: stepping motor + screw rod;

Total 999 model parameter can be set;

Machine will automatically stop once wire coil winding is finished;

4. Motor coil winding machine picture show:

a.The semi auto motor coil winding machine

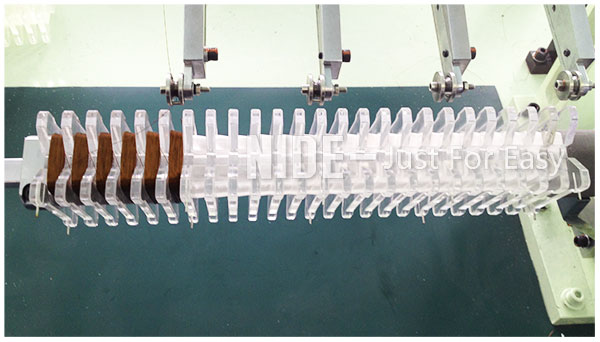

b. The semi auto motor coil winding machine mold

3. The semi auto motor coil winding machine winding process

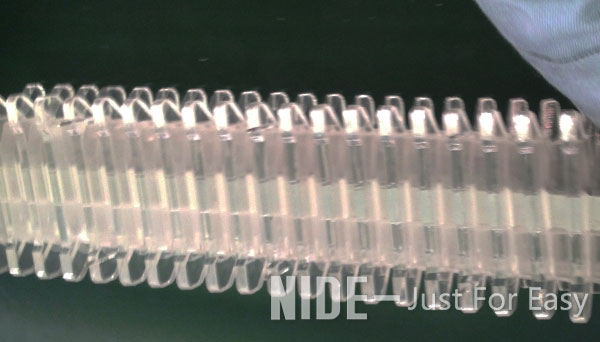

4. The semi auto motor coil winding machine wire frame

The semi auto motor coil winding machine video

About Motor stator manufacturing

Motor stator manufacturing production assembly line including paper inserting machine, coil winding machine, coil winding inserting machine, lacing machine, forming machine and testing machine.NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

About NIDE

Nide is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.We can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.We also provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machine's application

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English