Hairpin Motor Stator Slot Insulation Paper Inserting Machine

Model number:ND-CZ-250-200

Introduction:The Hairpin Motor Stator Paper Inserting Machine is used for new energy vehicles motor manufacturing.

- Specification

The Hairpin Motor Stator Paper Inserting Machine is used for flat wires with low slots.

Hairpin motors are currently mainly used in new energy vehicles. After years of development, and with the maturity of motor technology and equipment, motor windings have gradually developed from the previous round copper wire design to the flat copper wire winding design.

The motor is the key to the drive system of a new energy vehicle, and its performance is directly related to the dynamic performance of the new energy vehicle. New energy steam motors pursue high power, small size, high torque, and high speed (high power density, high torque density).

The hairpin motor meets the new energy vehicle's pursuit of high power density and high torque density of the motor, and is in line with the development trend of the industry.

Hairpin Motor Paper Inserting Machine Function

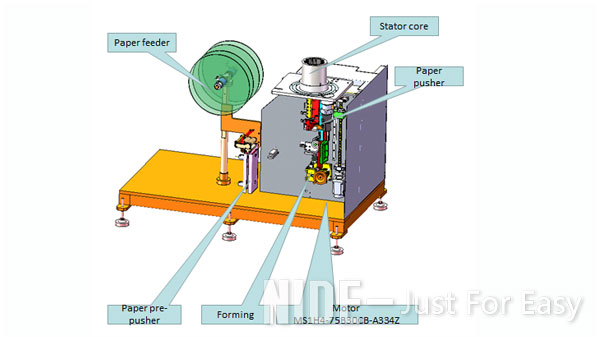

Vertical placed, convenient to change materials, repairing or replacing tooling.

With auto loading and unloading electrical arm, to pick up stator and load into paper inserting station.

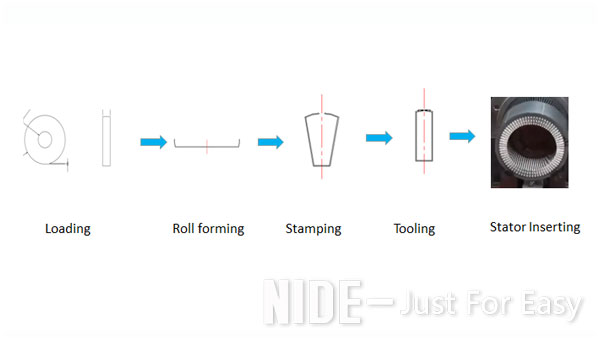

Auto paper indentation, feeding, cutting, stamping and forming, inserting and indexing, driven by servo motor and the mechanical cam.

Hairpin Motor Paper Inserting Machine Characteristic

Suitable for flat wires with low slots

Cycle time:around 2 sec/slot

With module design for tooling, steady and easy to switch

Auto stop while paper jam or lack

Able to pre-feeding, paper length inspecting, detect insertion quantities problem

With interface display to change specifications easily, equipping with auto alarm and diagnosis, manually and automatically operating

No damage to slot insulation with neat cuts and furless and no deformation or warped teeth for core after inserting

Safety functions for sense and auto stop and over-load protection

Basic information saved in PLC, able to upload data from every machine to MES system

Fully automatic, compatible with manual operation. Pre-debugging and parameter development process can be controlled manually.

Hairpin Motor Paper Inserting Machine parameters :

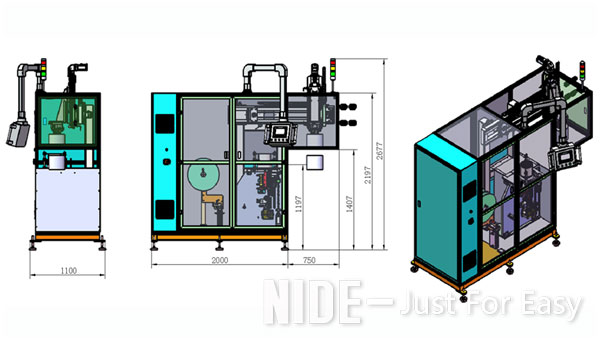

Product name: Hairpin Motor Paper Inserting Machine ID: 80-150mm OD: 130-250mm Stack length: 80-200mm Paper width: 25-50 mm Temperature: 10℃-45℃; Noise: ≤70dB Power: 380VAC±10%,50Hz; Control power: 24VDC Compressed air: 0.5MPa—0.7MPa Hairpin Motor Paper Inserting Machine structure

Hairpin Motor Paper Inserting Machine process

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English