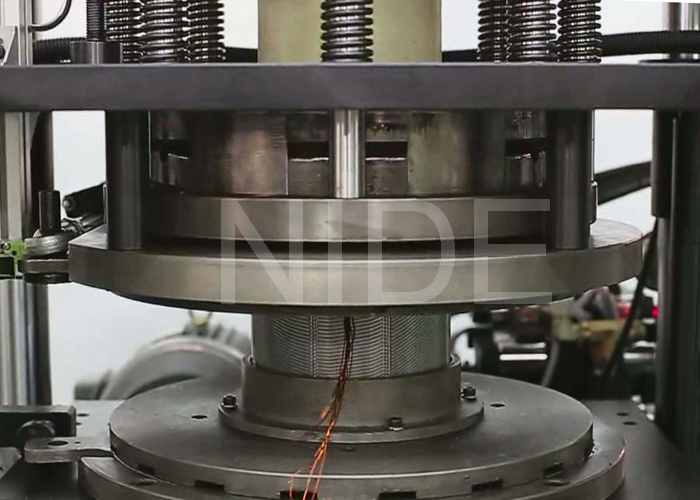

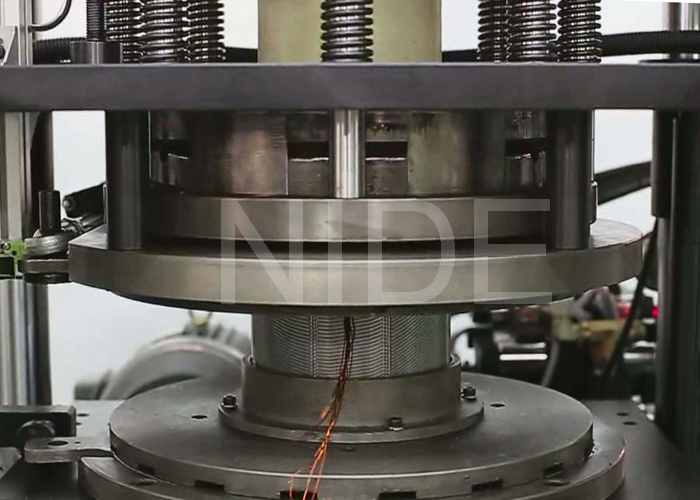

The coil forming machine is very easy to operate. Once put the stator in the working station, press the start button, machine will automatically do the forming process. The light curtain will protect the operator forming damage during machine running.

(1) Machine main function and characteristic

This machine adopts whole hydraulic system and PCL program.

This machine can adjust the forming stack length by changing washer.

This machine has five oil cylinders which work individually to expend inner coil, wrap outer coil and form hang over.

After forming, there is no copper wire enamel broken or wire snap. and coil OD and ID is close to the final forming dimension.

Both slot paper and wedge should not be damaged or turned over. The stator should not be deformation or stator lamination should not be upward. There is no wire enamel broken.

Production capacity ≤14s/set (exclude loading/unloading time)

Primary qualification rate ≥98.5%, after rework, the rate ≥99.5%

This machine adopts safety grating protection system. Operator need to stand when operating.

Machine adopts two hands simultaneously start button to ensure safety.

(2) Technical data

Stator ID: 30~110mm

Stator OD: Max. 160mm

Stator stack length: 20~150mm

Winding overhang: Max 45mm

Displacement of cylinder: 20F

Power: 380V/50/60HZ 3.75KW

Machine weight: about 800Kg

Machine dimension: (L)1200*(W)1400*(H) 2400mm

(3) Application

The motor stator coil forming machine is suitable for air conditioner motor, washing machine motor, compression motor, fan motor, generator motor and pump motor.

The forming tooling is pressing down.

About Motor stator manufacturing

Motor stator manufacturing production assembly line including paper inserting machine, coil winding machine, coil winding inserting machine, lacing machine, forming machine and testing machine.NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

About NIDE

Nide is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.We can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.We also provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machine's application

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English