stator coil shape expanding and forming machine

Model number:Z3XL3-110-160

Introduction:With high technology and stable performance, this final forming machine is of highly efficiency and qualified forming. it is equipped with and driven by the hydraulic system.

- Specification

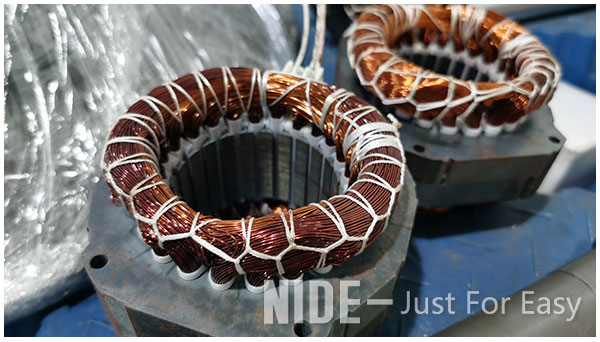

Automatic stator coil shape expanding and forming machine finally

With high technology and stable performance, this final forming machine is of highly efficiency and qualified forming. it is equipped with and driven by the hydraulic system. The displacement of cylinder is 20L/min. The machine tooling design adopts flexible principles of inner expansion. The outer wrapping and edge forming form the stator winding. It can ensure appropriate winding outside dimension after lacing.

Required information for quotation:

stator drawing before forming and after forming, including stator O.D, stator I.D, stator stack height, and end coil dimension.

Technical parameter:

ItemData

Size: (L)650×(W)950×(H)2300 Tooling included weight: Around 700 Power supply: 380V/50Hz three phase four wire power Working pitch time: ≤13 ID: Φ30~Φ120 OD: Φ50~Φ160 Stack height: 15~160 Tooling stroke: ≤70 Machine maintenance

When doing maintenance, please stop machine running and cut off the power. During machine adjustment or maintenance, please do not disassemble machine or change the mechanical and electrical system elements at random.

Each time before using, check mechanical, electrical, hydraulic, pneumatic and lubricating parts.

After work finished, clean up machine and reset machine to make all the parts to go back to original position.

Regularly check if there is water in the filter. If yes, discharge the water.

Regularly check if there is sufficient oil in the atomized lubricator. If not, replenish it.

Regularly check the lubricating condition of guide mechanism, replenish if necessary.

Check and clean up the electrical cabinet once every three months.

Check solenoid valve screws and pipe connectors once every 3 months.

Check filter once every 2 months.

Competitive advantages

Variety of application, easy operation.

We have Overseas Service Center.

Machine is controlled by PLC. All the parameter can be set in the touch screen.

It is suitable for stators with different model number and dimension.

The operation and tooling change process is easy.

We could customize machine for our customer as per their requirement.

We directly supply our machines to many countries, like USA, France, Turkey, Iran, India, Brazil, Argentina, Mexico etc.

About Motor stator manufacturing

Motor stator manufacturing production assembly line including paper inserting machine, coil winding machine, coil winding inserting machine, lacing machine, forming machine and testing machine.NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

About NIDE

Nide is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.We can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.We also provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machine's application

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English