Automatic Three-pin Linear Stator Coil Winding Machine

Model number:ND-SLR01C

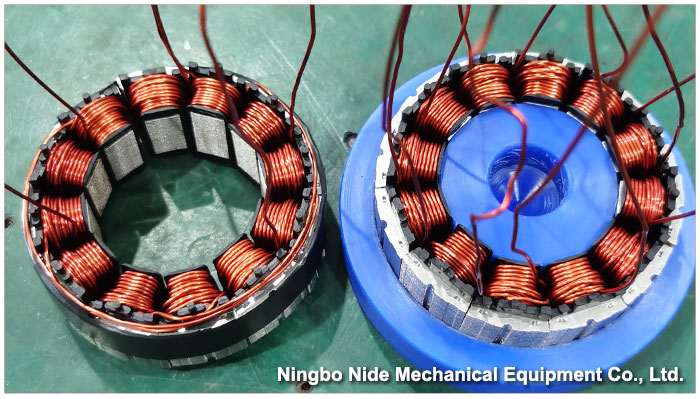

Introduction:This needle winding mahcine is used for three-pin straight winding process. Suitable for BLDC motor segmented and linear stator coil winding.

- Specification

Automatic Three-pin Linear Stator Coil Winding Machine

This BLDC needle winding machine is used for three-pin straight winding process. Used for multi-pole linear stator winding: the equipment can wind 3-slot stators at the same time with each movement, greatly improving production efficiency. Suitable for BLDC motor segmented and linear stator coil winding.

I. Main performance and characteristics of equipment

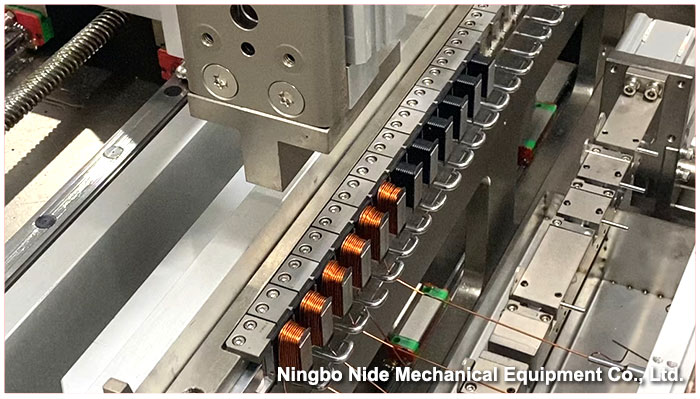

1. Used for multi-pole stator winding: the equipment can wind 3-slot stators at the same time with each movement, greatly improving production efficiency.

2. Manual loading and automatic mold clamping which reduce the manual efforts.

3. The winding process can realize multiple tapping (screen settings), thread clamping, and thread trimming functions.

4. The number of slots and turns can be set through the human-machine interface.

5. Different molds can be replaced to match with the different specifications of the stator to be produced. The winding parameters can be used for different stators and the winding parameters can be quickly switched through the human-machine interface to comply with the requirements of different stators.

6. The equipment has alarm output function.

7. Safety performance: This machine adopts safety protection system and safety door switch protection. Dual start, safety guards for picking and placing materials.

8. Used for straight stator winding, manual loading and unloading, automatic clamping, automatic winding, automatic pole changing, automatic tapping, automatic hooking, pneumatic cutting of the first and last wires.

9. The equipment has single action/stepper/automatic mode which can be converted into each other. Suitable to operate the three winding methods (Consecutive poles / Complete phases / Complete stator) in the attachment.

10. Full sheet metal plus PC board protection.

II. Winding machine technical parameters:

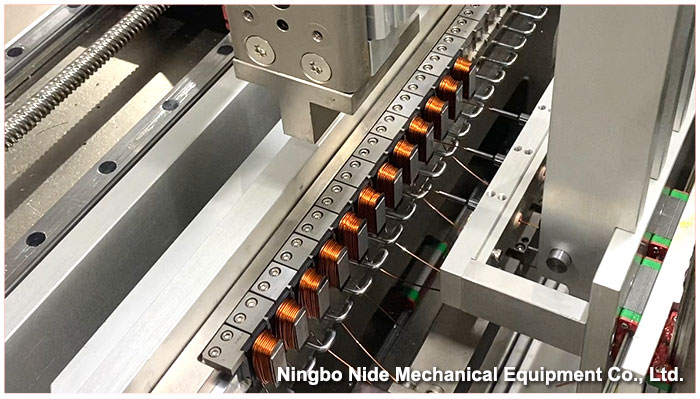

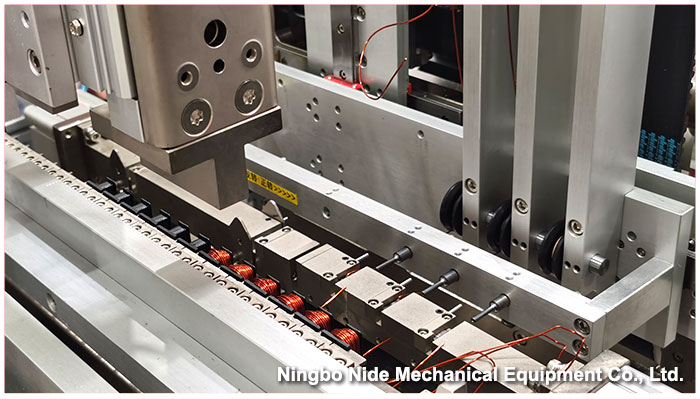

Production name : Three-pin Linear Stator Coil Winding Machine Max Stator diameter: Up to 120 mm Stack length: Up to 50 mm Teeth number: Up to 36 slots Wire diameter: Up to 1.6mm (tensioner needs to be replaced for different wire diameter ranges) Winding method: suitable to operate the three winding methods (Consecutive poles / Complete phases / Complete stator) Production cycle time: MAX 80sec. The passing rate of winding: ≥ 99 %. Cycle Time: ≤80 sec/piece (12 poles) Air pressure: 0.4~0.7 MPa Power supply: 380V/50HZ three-phase four-wire Total power: 12 KW Dimensions: Length1850*width2350*height1800mm Weight: About 950Kg III. Linear Stator Winding Machine Picture

IV. Linear stator winding machine video

About NIDE

Nide is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.We can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.We also provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machine's application

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English