Automatic Servo Control Stator Wire Lacer

Model number:BXSIIL1-160/160-6

Introduction:This stator lacing machine is equipped with two needles, therefore, it can do lacing for the top and bottom coil at same time, so that it saves time and improve the working efficiency.

- Specification

This stator lacing machine is equipped with two needles, therefore, it can do lacing for the top and bottom coil at same time, so that it saves time and improve the working efficiency

(1) Machine main function and characteristic

This machine adopts servo driven system, CNC control design and HIM program.

The indexing is driven by servo system. Different lacing mode could be set such as slot lacing, interval lacing, and fancy lacing.

Main spindle adopts servo control system. The rotation speed can be set.

Two needles driven by servo system lace upper and lower coil simultaneously.

Machine can automatically feed thread and cut thread. There is no need to tie a knot.

Tooling change is fast and convenient. Stator stack length range is 50-130mm.

Lacing tension can be set,

Production capacity ≤1s/slot.

Should be no copper wire snap and wire enamel broken.

Primary qualification rate ≥98.5%, after rework, the rate ≥99.5%

his machine adopts safety grating protection system. Operator need to stand when operating.

Machine adopts two hands simultaneously start button to ensure safety.

(2) Technical data

Stator ID: 40~100mm

Stator OD: Max. 160mm

Stack length: 30~160mm

Over-hang height: Max. 65mm

Lacing mode: slot by slot/ interval slot/ fancy lacing

Lacing speed: 0.5s/s

Power: 380V/50/60HZ 3.5KW

Machine weight: about 600kg

Machine dimension: L1500*W650*H1700mm

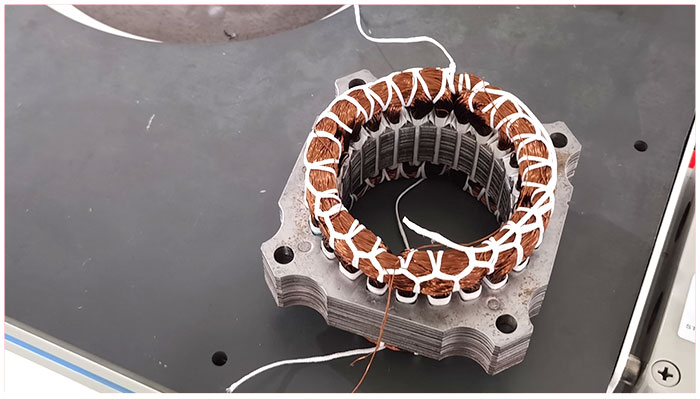

(3) Application

It is suitable for air conditioner motor, washing machine motor, compression motor, fan motor, generator motor and pump motor.

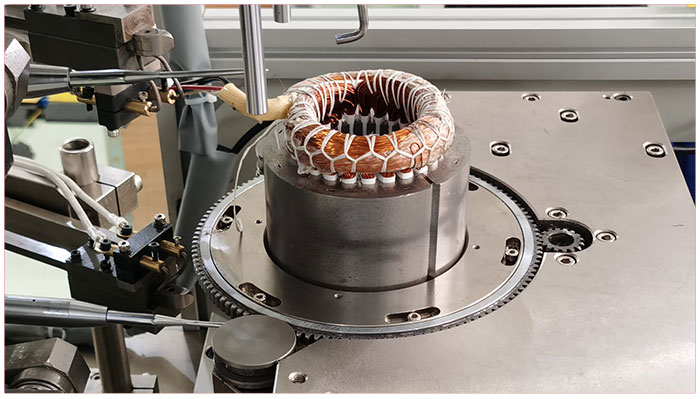

Stator loading area of this lacing machine

Automatic Servo Control Stator Wire Lacer youtube video

About Motor stator manufacturing

Motor stator manufacturing production assembly line including paper inserting machine, coil winding machine, coil winding inserting machine, lacing machine, forming machine and testing machine.NIDE can supply and manufacture about then ,and all the process will be done by machine automatically. Operator only needs to do loading and unloading.

About NIDE

Nide is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line.We can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.We also provide technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machine's application

Our machines are mainly applied to induction motors, BLDC motor, universal motor, three phase motor, single phase motor, AC motor, DC motor, such as washing machine motor, air conditioner motor, pump motor, cooler motor, alternator motor, fan motor, ceiling fan motor, compressor motor, power tool motor, vacuum cleaner motor, mixer motor, series motor, electrical car motor, wheel hub motor, electric toothbrush motor, hair dryer motor, electric shaver motor,etc.

Contact us

Motor Manufacturing Solution

Email : emarketing@nide-group.com; marketing8@nide-group.com;

SNS

中文版

中文版 English

English