The EV Revolution Drives a Need for Precision in Motor Manufacturing

As the global shift toward clean energy accelerates, the electric vehicle (EV) industry continues to surge.

To meet rising demand, EV manufacturers require motor production processes that are fast, precise, and scalable.

At the core of this process is the coil winding machine — a crucial piece of equipment that ensures consistent

winding quality, enhances energy efficiency, and reduces operational costs.

Designed for BLDC and Induction Motors

The majority of EVs rely on BLDC (Brushless DC) motors and 3-phase induction motors. Our automatic coil winding

machines are tailored to these motor types, offering:

Multi-slot parallel winding

Cross-slot winding

Dual-head synchronous winding

These features allow manufacturers to handle various stator sizes and coil specifications with speed and accuracy.

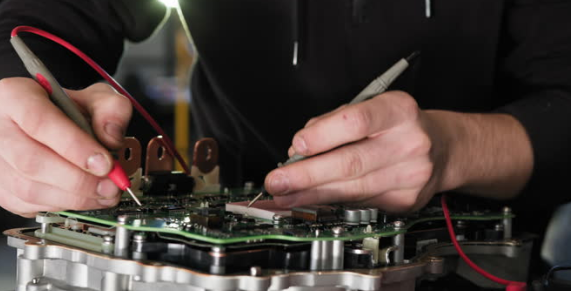

Smart Control Systems for Smart Manufacturing

Today’s factories require intelligent machines. Our coil winding systems are equipped with:

Graphical programming interfaces

Remote diagnostics and program switching

Real-time tension control and insulation detection

These capabilities simplify operation, reduce error rates, and support batch flexibility — ideal for both large-scale

production and custom motor lines.

Trusted Worldwide

Our coil winding machines are used in EV motor production lines across Europe, Southeast Asia, and South America.

They are ideal for:

New energy vehicle motor factories

Tier 1 automotive component suppliers

OEM/ODM manufacturers of industrial motors

Recommended Models

Here are several proven solutions from NIDE for high-performance coil winding:

ND-RM-AL2-N02 – Automatic Armature Winding Machine

Supports 3–24 slots with 4 working stations, ideal for high-efficiency armature coil production.RXL1-160A – Double-station Automatic Stator Coil Winding Machine

Vertical structure, suitable for multi-size stators, wire diameter range: 0.17–1.2 mm.ND-SW01 – Needle Winding Machine for BLDC Motors

Optimized for precise and fast winding of brushless motor stators with multi-slot designs.

Conclusion

The success of EVs depends on smarter, faster, and more precise production lines. Investing in advanced coil winding

equipment is not just an upgrade — it's a future-proofing strategy for forward-looking manufacturers.

中文版

中文版 English

English