Understanding the Spot Welding Manufacturing

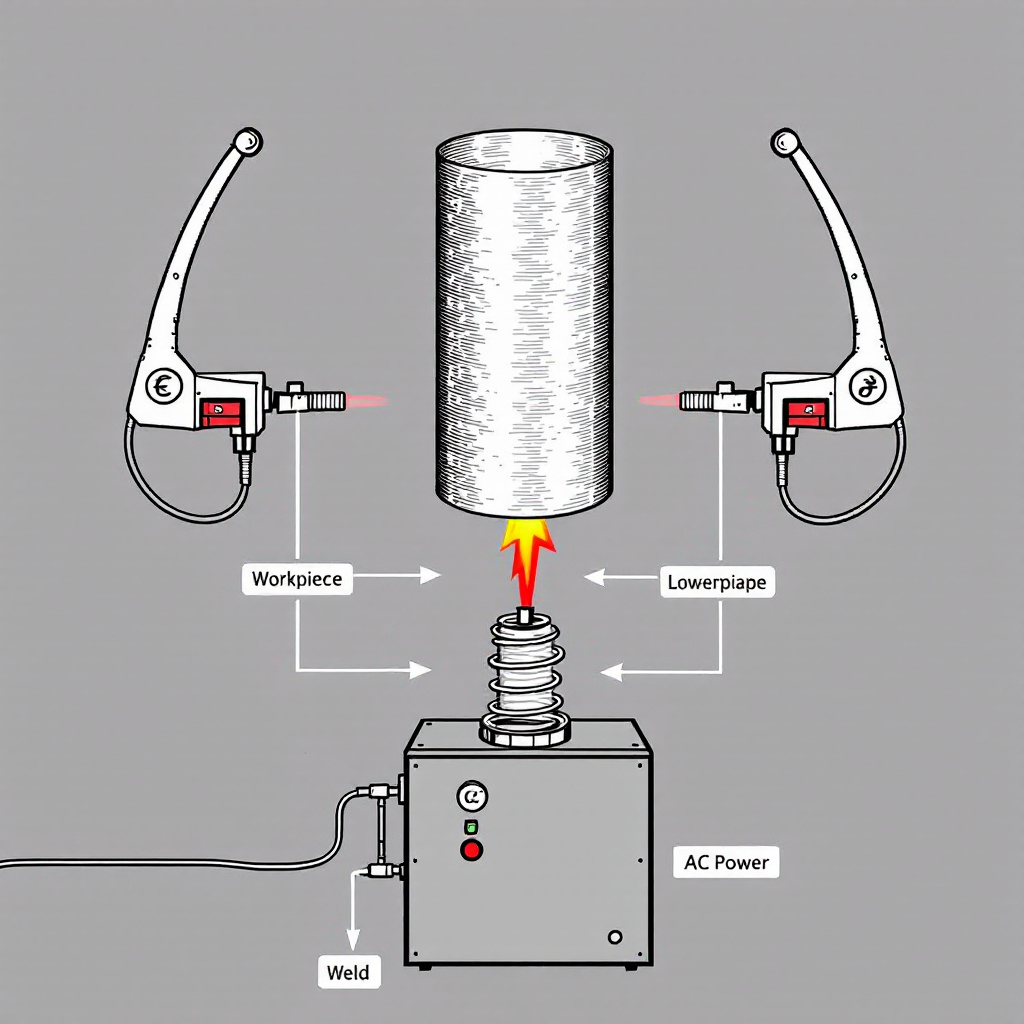

What is spot welding process? It is a resistance welding technique that joins metal parts

by applying pressure and heat through an electrical current. The process is fast and efficient,

making it ideal for high-volume manufacturing such as motor assembly. With advancements

in spot welding equipment, modern factories achieve consistent weld quality with minimal defects.

Application of Spot Welding in Stator and Rotor Assembly

1. Stator Assembly

The stator is the stationary part of an electric motor, consisting of laminated iron coresand

copper windings. Spot welding is widely used to:

Secure the laminated iron sheets together, preventing movement and reducing energy losses.

Weld connection points between winding terminals for stable electrical conductivity.

2. Rotor Assembly

The rotor is the rotating component that interacts with the stator to generate motion.

Spot welding helps in:

Bonding rotor laminations to maintain structural integrity.

Attaching electrical leads and connectors efficiently.

Advantages of Spot Welding in Motor Manufacturing

Using a spot welder machine for stator and rotor assembly offers several advantages:

Speed and Efficiency: Spot welding is a rapid process that enhances production rates.

Strong and Durable Joints: Ensures reliability in high-performance motors.

Minimal Heat Distortion: Unlike other welding methods, spot welding produces less

heat-affected zones, preserving material properties.

Cost-Effectiveness: Compared to alternative methods, spot welder cost is relatively

low for mass production.

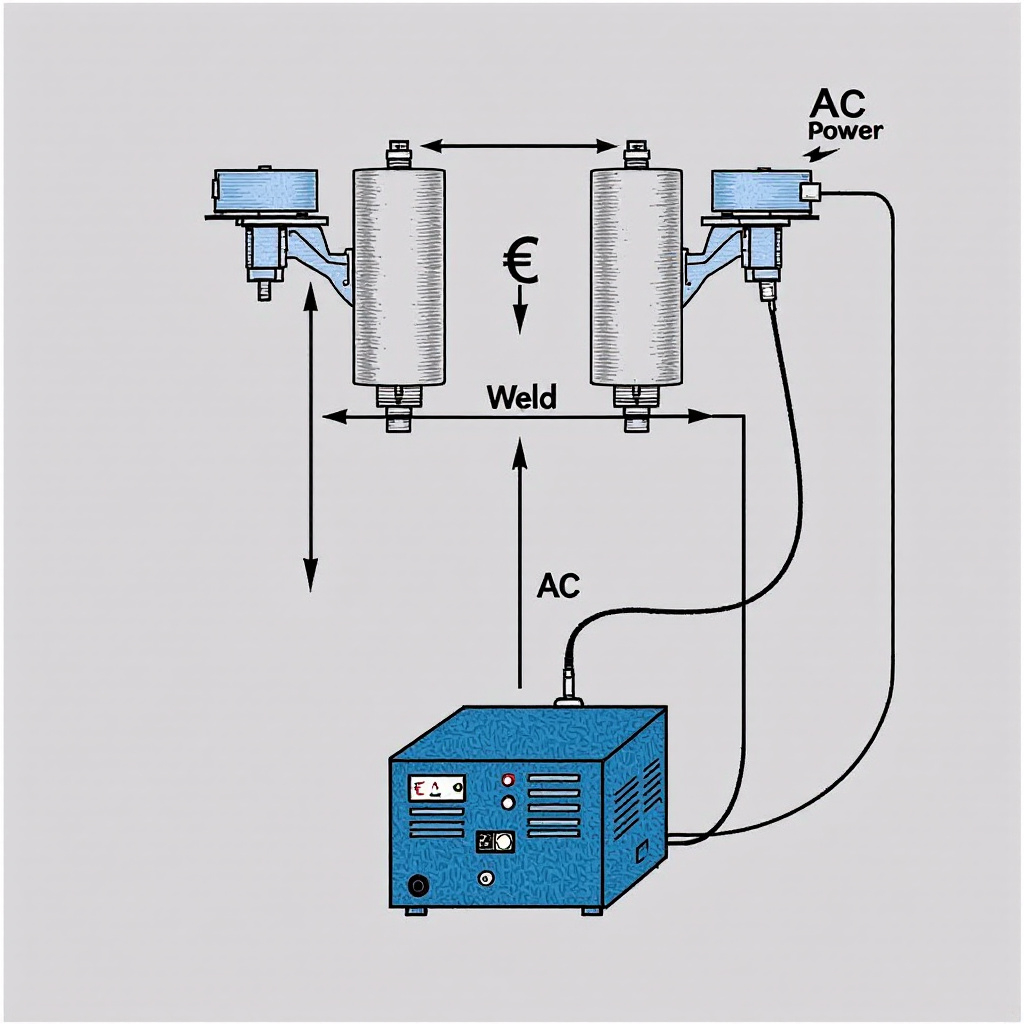

Choosing the Right Spot Welder for Motor Manufacturing

The type of spot welding equipment used depends on production needs. Some key

considerations include:

Portability: A portable spot welder is ideal for on-site or small-scale operations.

Industrial Use: Factories often use automated spot welder auto body machines

for large-scale manufacturing.

Manufacturers in different areas can look for options like spot welders. They can

find them in the U.S. or search for spot welders in Australia for local sourcing.

Spot Welding Defects and How to Avoid Them

Despite its advantages, improper use of spot welding board and equipment can

lead to defects like:

Cold welds: Due to insufficient heat or pressure.

Expulsion of molten metal: Caused by excessive current.

Electrode wear: Reducing weld consistency over time.

To prevent these issues, technicians must implement regular maintenance of spot welding

equipment and quality control measures.

Conclusion

Spot welding is an essential process in electric motor manufacturing, particularly in assembling

stators and rotors. Using a spot welder for car repairs or large-scale production makes strong,

efficient, and cost-effective connections. By understanding the spot welding process and choosing

the right spot welder, manufacturers can get great results. This improves motor performance

and makes them last longer.

中文版

中文版 English

English